Since the 1990s Güssing has evolved into a trend-setting energy region through a comprehensive energy-efficiency programme (thermal insulation, use of LEDs) and the broad implementation of renewable energy sources (e. g. district heating and photovoltaics) to generate heat and electricity, also attracting great attention internationally as a leading environmentally friendly region with its more than 30 demonstration facilities.

One of the reasons for success is the close links and cooperation between industry, equipment suppliers and research institutions. After the founding of the European Center for Renewable Energy (EEE) in 2002, Güssing became a research location with a European reputation. In 2009 the research center “Technikum” with a focus on biomass gasification and synthetic fuels was opened as part of the COMET programme. The Technikum in Güssing is one of several locations for the “Bioenergy 2020+” competence centre, where, amongst others, the Vienna University of Technology, Graz University of Technology and Joanneum Research are involved.

Bioenergy Technologies in Practice

One of the most important innovations is the Güssing biomass power station with 8 MWth, powered since 2001 by DUAL FLUID steam gasification technology developed specially at the Vienna University of Technology to process ligneous biomass. In the case of DUAL FLUID gasification the gasifying and combustion processes take place in two separate fluidized-bed reactors; in the gasification section the fluidizing medium is steam, in the combustion section air. The output is nitrogen-free producer gas low in tar with a calorific value of 12 MJ/m³.

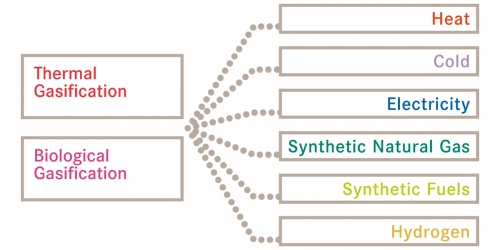

Due to the producer gas’s advantageous characteristics there are many possible usages: simple conversion to electricity and heat in gas engines or turbines, producing renewable synthetic natural gas (BioSNG) or hydrogen, finally high-grade synthetic products such as Fischer-Tropsch diesel fuel, kerosene and petrol (BTL – Biomass to Liquid, 2nd-Generation Fuels).

Various ways of exploiting the possibilities are currently being examined as part of on-going international projects; some have already been successfully demonstrated. In 2008 wood-based producer gas from a biomass power station was converted to synthetic natural gas for the first time worldwide. Beside wood chips, it is basically also possible to use other carbonaceous raw materials for this process. Apart from thermal gasification, Güssing also practices biological gasification of carbonaceous raw materials in bio-gas facilities. Various materials from the region (e. g. agricultural residual materials, straw, etc.) are drawn on for this. There are plans for supplying energy via a local biogas grid and further increasing the number of natural-gas filling stations.

The new technologies tested in Güssing form the basis for future energy supply hubs which meet all needs regarding heat, electricity and fuels from resources available in the region, without competing with the food industry for materials. Research and Development create added value and help to protect the environment.