At Innsbruck University a pioneering system to store electricity locally is currently being developed and demonstrated in the hydraulic engineering field. The Powertower is a hydraulic energy storage facility based on the established technology of pumped-storage power stations, and operating at a similar level of efficiency. To store energy the facility generates potential energy; however, in contrast to pumped storage a difference in altitude is unnecessary. The system is flexible and can be employed independently of terrain; it is easy to integrate in new local energy supply structures, e.g. with wind farms or as decentral storage directly linked to local grids or industrial applications.

Straightforward operating principle

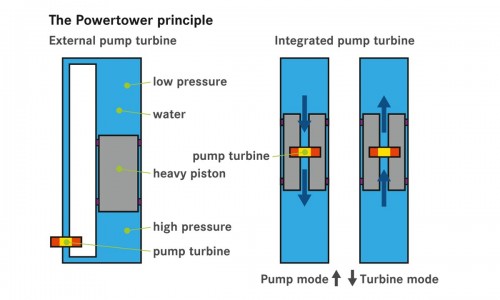

To generate potential energy, a pump raises a piston vertically in a cylinder filled with water. When the imposed load drops it drives a turbine, feeding the energy recovered into the grid. The larger and heavier the imposed load is, the more energy the system can store. If the upload is half as high as the outer cylinder, the maximum energy content of the system results. There is no limit to the number of cycles, and rapid load alternation is perfectly possible. Given its straightforward, robust design, a long service life (> 50 years) and low running costs can be predicted for the Powertower. Storage capacity is scalable, and can be adapted to the specific application on hand. For really large projects several Powertowers can be grouped together in a cluster and controlled collectively; this makes the approach even more cost-effective.

Small-scale tests

A series of small-scale tests at Innsbruck University has established that the system is fully capable of accommodating voltage fluctuations and uneven rates of power supply. A multi-stage plan is envisaged for development to commercial viability.

The first small-scale test was implemented with an external pump turbine, using a plexiglass cylinder 2.20 meters tall and 0.64 meter in diameter, filled with water, and a steel piston with vertical travel, weighing 1.5 tons. The Powertower in the second test is 6 meters tall and 2.30 meter in diameter; it is made of prefabricated concrete elements and has an internal pump turbine. Here the cylinder wall is made of fibre-reinforced plastic.

To work properly the Powertower needs a satisfactory sealing system to ensure that the cylinder cross-section can be closed off 100 %, interrupting flow between the lower and upper reservoirs and preserving the current energy potential. Large Powertowers will need more flexible seals to accommodate geometrical distortions in the cylinder wall.

A large-scale test is currently being prepared, where a Powertower 20 to 30 meters tall and nearly 15 meter in diameter will be realized. The aims here are to show that the system works on a semi-industrial scale, to develop the seal and travel arrangements and to fine-tune the structural and mechanical engineering. The next step will then be to develop a prototype 50 to 100 meters tall with a storage capacity of > 1 MWh. It is intended to achieve commercial viability by 2020, with the option of grouping several Powertowers in a cluster.