With energy costs going up and consumers making more responsible choices, energy efficiency in production is now a decisive competitive advantage for many manufacturers. Methods and tools for improving energy efficiency normally address individual aspects of a production facility; so far there has been no systemic, holistic approach to analysing and improving energy and resource flows in production in combination with estimating the economic effects of the relevant steps. In its BaMa project, the Institute for Production Engineering and Laser Technology (IFT) at TU Wien (Vienna University of Technology) has developed a simulation-based methodology for planning and controlling energy consumption in industrial production. Application-oriented software tools make it possible to minimize energy consumption in production processes, taking the economic factors time, cost and quality (which are vital for success) into account. 18 partners from research and industry collaborated in the lead project of energy research.

The BaMa System

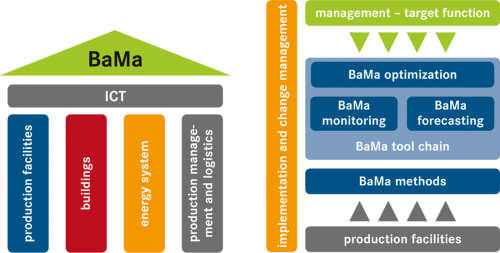

The Balanced Manufacturing System enables manufacturers to analyse and forecast energy consumption in production processes and to reduce it by means of adaptive operating strategies. All the relevant modules of a production unit (production, buildings, energy, logistics) are modelled, taking management aspects into account. The method involves a modular approach: the production facility is divided into individual segments with defined system boundaries (so-called “cubes”), identified by clearly specified interfaces. This makes it possible to identify subsystems with especially large influence on the energy consumption of the system as a whole. Broad assessments of energy consumption at product level are derived from energy and resource flow analyses, and a product footprint (time, costs, energy, carbon-dioxide emissions, etc.) is drawn up.

Demonstration

The methods and software tools developed are currently being tested in production facilities owned by MPREIS and Infineon Technologies Austria, two of the project partners. Energy

savings in the range of 10 to 20 % are expected for both applications.

The supermarket chain MPREIS puts the tools to work in its large bakery “Bäckerei Therese Mölk”, where the energy factor is being taken into account for the first time in production planning. As a first step, energy consumption for all products and manufacturing processes was recorded and a simulation model drawn up to map real production. Next, the project team developed an optimization tool in which all production variables (locations, times of day, energy demand, etc.) are harmonized. In total, all four production lines where included in the system.

At Infineon Technologies Austria, a semiconductor manufacturer, the BaMa system is being used to improve the operating strategy for chillers. Semiconductors are manufactured in clean rooms, in which a specific temperature and humidity are required. These rooms are air-conditioned by chillers which consume a great deal of energy. In the course of the project potential for improvements in regulating and loading the chillers is identified, and recommendations for action are worked out.

The software tool chain comprises the following core modules:

> monitoring function: data on resource consumption are gathered, edited and visualized

> forecasting function: starting from the product footprint and the production plan, the factory’s energy consumption is forecasted

> optimizing function: on the basis of data from and numerical simulation models of the fabrication subsystems, the operating settings for the production facility are adapted to approximate the targets (reducing energy consumption, processing time and cost and improving product quality).