Taking the food industry as an example, an innovative concept for decarbonising industrial energy supply systems has been developed and tested as part of the EDCSproof1 NEFI project based on digital applications as well as heat pumps and energy storage systems. EDCSproof stands for “Energy Demand Control System – PROcess Optimization For industrial low temperature systems”. The project focused on developing a regulation concept that is online, predictive, holistic and reconfigurable and that is to be used to implement sustainable energy concepts in industry in the future.

EDCSproof performs various roles::

> The system supports the integration of renewable energy sources using energy storage systems

> It acts as a flexible consumer for power grids (demand-side management, taking account of dynamic tariffing)

> It increases efficiency by optimising control of the overall system

> It enables waste heat to be harnessed using high-temperature heat pumps (<150 °C), meaning that energy demand can be reduced while maintaining production at the same high level

A user-friendly human-machine interface enables the efficient input of production schedules as well as the visualisation of current and forecast plant conditions and allows operators to intervene in the processes.

Work steps

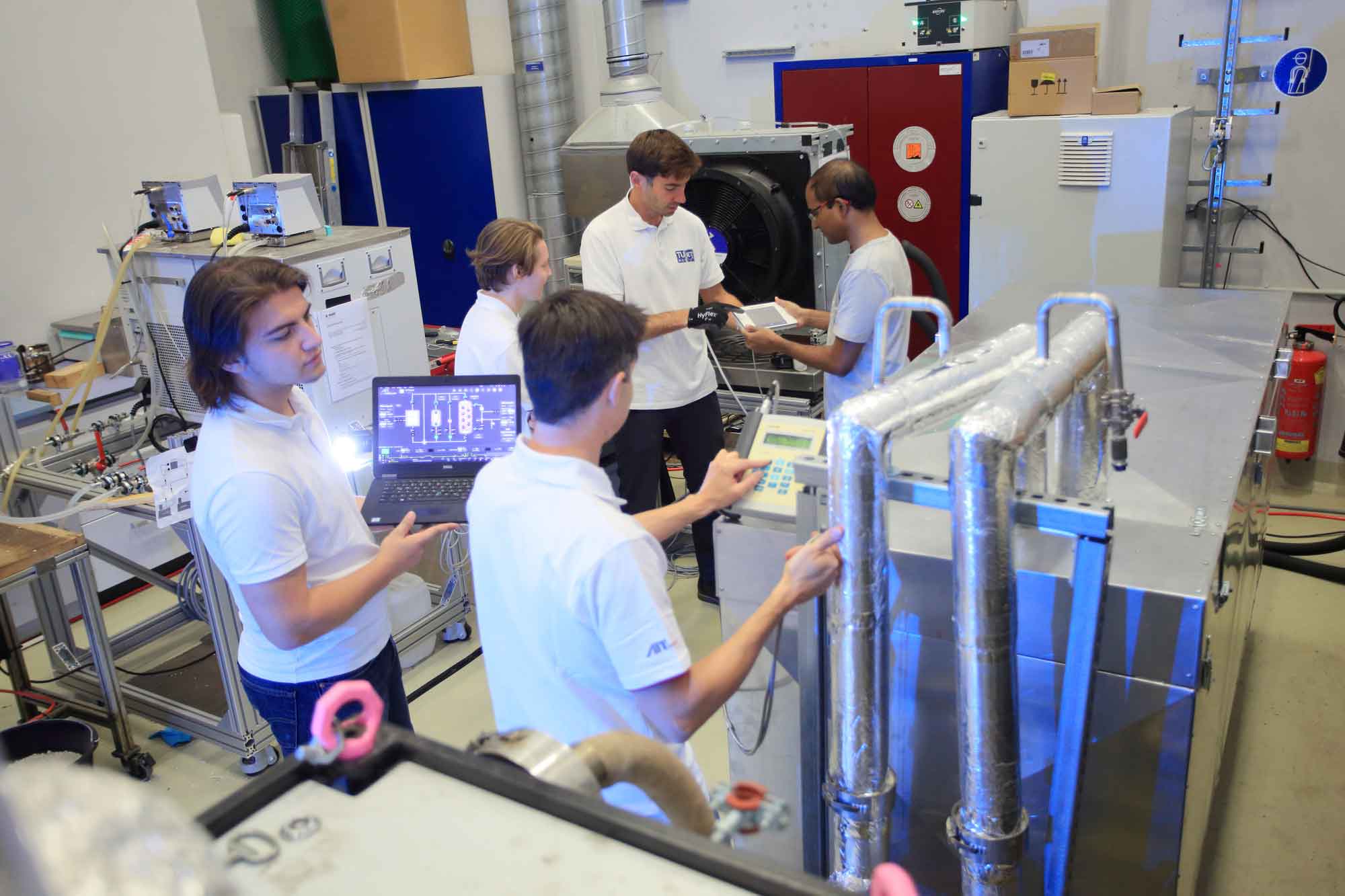

Three sites operated by the project partners from the food industry (Wiesbauer Holding AG, Fischer Brot GmbH) were analysed as part of the project. This analysis then served to determine a reference energy system, targets for optimisation and framework conditions for integration in energy markets. Models for energy supply, storage and consumption were produced and used as a basis for devising and testing the energy demand control system (ECDS) in the laboratory. This was followed by techno-economic and environmental analyses. Scalability for additional industrial applications was also investigated, and the latent heat storage technology was developed further and tested.

Outcome of the project

An energy supply system with defined boundary conditions (energy prices that fluctuated over time, emission factors and availability of waste heat sources) was used as an example to demonstrate in the laboratory that the EDCS can help cut emissions by up to 57 % and energy supply costs by 8 % compared to a standard controller. Integrating the EDCS allows the potential for added flexibility to be leveraged to the full without modifying the existing infrastructure. The actual savings potential will depend on the individual situation facing each company and, specifically, on the structure of its energy supply system, the possibilities for storing energy and the scope for flexibility in consumption. The project produced an energy concept spanning across all sectors and with a broad field of application, which can be implemented at the project partners’ sites as well as at other companies. The system is making a major contribution to increasing energy efficiency and thus the competitiveness of the manufacturing sector and is paving the way for a switch to renewable energy sources in industrial energy supply.

Further development

The follow-up project “Industry for Redispatch”2, which is currently under way, aims to further develop and implement the EDCS controller in industrial plants while also giving them flexibility in terms of the power grid. Its partners are Wiesbauer Holding AG, the paper manufacturer Mondi, voestalpine Stahl GmbH, Siemens AG and APG Austrian Power Grid as well as several distribution network operators and research organisations.

https://www.nefi.at/edcsproof/

„The EDCSproof research project clearly demonstrates economic benefits of data collection and analysis in manufacturing industry. Together with partners from industry and research, we worked on efficient solutions toward a climate neutral manufacturing plant. By developing an Energy Demand Control System we are a big step closer to reach this goal. Now it’s time for implementation.“

Magdalena Teufner-Kabas

Managing Partner, kleinkraft OG

1 Project partners: AIT Austrian Institute of Technology GmbH (project management), Montanuniversität Leoben/Chair of Energy Network Technology, TU Wien/Institute for Energy Systems and Thermodynamics und Institute of Mechanics and Mechatronics, Control and Process Automation, evon GmbH, ILF Consulting Engineers Austria GmbH, kleinkraft OG, Wiesbauer Holding AG, Fischer Brot GmbH

2 www.nefi.at/industry4redispatch/

EDCSproof is part of the NEFI (New Energy for Industry) model region Share