Heat pumps are used these days to heat rooms and produce hot water in many different types of buildings. They will play an increasingly important role in the energy system of the future, with the goal of reducing greenhouse gas emissions in the building sector. Heat pump technology also enables numerous other applications, such as providing heat to district heating networks and for industrial processes. Improving energy efficiency is a key topic in manufacturing plants. Many companies also generate significant amounts of waste heat from different areas and processes, with much of this remaining unused up to now. However, in industry and commerce heat pumps are still rarely used at the present time. Of the 61,677 heat pumps installed in Austria in 2022, only 131 of these were industrial heat pumps.1

The IEA Heat Pumping Technologies Programme includes a project specifically dedicated to the topic of High-temperature Heat Pumps (Annex 58)2. This is focused on heat pumps with supply temperatures above 100°C. Expertise from the member countries is processed in a structured manner in order to gain an overview of the technological options available with high-temperature heat pumps. Integration of heat pump systems into different industrial processes is a key topic.

Descriptions are being developed of high-temperature heat pump concepts for selected industrial processes (e.g. brick drying or steam generation) in order to help potential end users and answer their questions on the applicability of the technology in their processes. Examples are also collected and published showing the large variety of heat pump technologies available on the market as well as demonstration projects in the high-temperature range. Guidance is also being developed to support companies in developing their decarbonisation strategy. Heat pumps have major potential here, as the technology is both a way to increase efficiency as well as a measure for electrification.

www.nachhaltigwirtschaften.at/en/iea/technologieprogramme/hpp

www.nachhaltigwirtschaften.at/en/iea/technologieprogramme/hpp/iea-hpt-annex-58.php

1 Innovative energy technologies in Austria: Market development in 2022, Federal Ministry for Climate Action, Environment, Energy, Mobility, Innovation and Technology (BMK)

2 Participating countries: Austria, Belgium, China, Canada, Denmark, France, Finland, Germany, Netherlands, Japan, Norway, South Korea, Switzerland, USA

![]()

Large-scale heat pump – Spittelau waste incineration plant

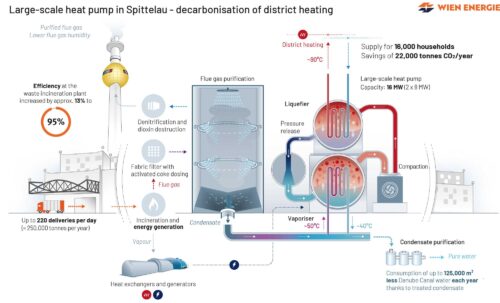

Vienna’s district heating system is already considered to be a pioneering model for environmentally friendly heating. The plan is for 56% of heating requirements in Vienna to be covered by district heating by 2040. Wien Energie’s aim is for 100% of the heat that it produces to be climate-neutral by then, using resources that include large-scale heat pumps and geothermal energy. The third large-scale heat pump with a capacity of over 10 megawatts is currently being built at the Spittelau waste incineration plant. The state-of-the-art 16 megawatt plant will supply 16,000 households with climate-friendly district heating from spring 2025, thereby saving around 22,000 tonnes of CO2 per year.

Waste heat from flue gas purification

Wien Energie uses the Spittelau waste incineration plant to generate electricity and heat for households in Vienna. The incineration process produces flue gases that are filtered and purified as part of a multi-stage process. The pollutants from the flue gas are bound in water, then the water is purified, cooled and discharged back into the Danube Canal. The waste heat remaining in the flue gas is released into the air via the chimney. Starting in 2025, Wien Energie will use heat pumps to utilise this waste heat for the district heating system. With the help of heat exchangers, the energy will be extracted from the condensate (water) produced when the flue gas is cooled and then utilised in the highly complex system to generate heat at around 90 degrees Celsius for Vienna’s district heating network..

A highly efficient process

Wien Energie is increasing the efficiency of the entire waste incineration plant by around 13% to over 95% through use of the heat pumps. This means that almost all of the necessary energy for the process is also utilised efficiently. Once the heat energy has been extracted, the cooled water from the flue gas condensation is treated and fed back into the waste incineration plant process. This saves water resources, as Wien Energie needs up to 125,000 cubic metres less water per year from the Danube Canal for the waste incineration process as a result.

Key data from the Spittelau large-scale heat pump

> Construction started in the spring of 2023

> commissioning scheduled for early 2025

> Plant capacity: 16 megawatts thermal (two heat pumps at 8 MW each)

> It will supply around 16,000 households in Vienna

> Savings of around 22,000 tonnes of CO2 per year

> EUR 40 million investment

www.wienenergie.at/blog/fernwaerme-zukunft

The project is part of the “Thermaflex” lead project and is being implemented as part of the Green Energy Lab research initiative.

www.greenenergylab.at