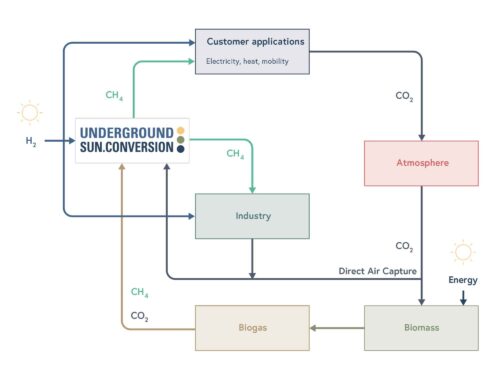

Strategies for the decarbonisation of industry aim to avoid the production of CO2 as far as possible in the future. However, in many branches of industry, such as steel production, carbon is still a technologically indispensable component of the production process. Innovative solutions are therefore being sought to capture and sustainably utilise the climate-damaging gas produced in these processes. In the Carbon-Cycle Economy Demonstration (C-CED) lead project, which is being carried out by RAG Austria AG together with industrial and research partners1, various CO2 capture and utilisation technologies and their interactions are being researched for the first time. The aim is to establish a sustainable closed carbon cycle. CO2 is captured on a pilot scale from various sources, e.g. from the exhaust gas streams of voestalpine steel production, and subsequently converted into valuable methane. The technical and scientific investigations are supplemented by techno-economic analyses.

Research and/or demonstration of CO2 capture from real gases

> Amine scrubber for CO2 capture from steel industry waste gases

> CO2 capture via membrane separation process

> Utilisation of CO2 contained in biogas

> Development of a new direct air capture (DAC) process

CO2 utilisation through methanisation

> Bioelectrochemical processes

> Flexibilisation of geomethanation in RAG’s “Underground Sun Conversion” project

Sustainably utilising CO2

The concept envisages pumping the captured CO2 in a concentrated and compressed state together with green hydrogen into natural underground storage facilities whose original content, natural gas, has been extracted. At a depth of around 1,000 metres, microorganisms living there combine the two gases in a biological process to produce renewable methane, the main component of natural gas. The sustainably produced methane can then be extracted and used in industry or to generate electricity. This once again produces CO2, and the cycle begins anew. The technology developed by RAG Austria AG for the injection and storage of green hydrogen in underground storage facilities and the concept of subsurface methanation have already been tested in previous projects (see articles in eia issues 4/2023, 5/2021 and 4/2017). The aim is now to establish a closed carbon cycle economy. The C-CED project builds on the investigations of RAG’s USC FlexStore project2. The inclusion of seasonal large-volume storage systems helps to create the flexibility required in a renewable energy system. trägt dazu bei, die in einem erneuerbaren Energiesystem notwendige Flexibilität zu schaffen.

voestalpine amine scrubber for CO2 capture

One source of CO2 in the C-CED project is exhaust gases from the voestalpine steelworks in Linz. A pilot plant for CO2 capture was put into operation at this site in the first half of 2023. The flue gas containing CO2 is extracted directly from a power plant chimney and fed into the separation plant, the eighteen-metre-high amine scrubber. In the first step, the CO2 forms a chemical compound with the amine washing solution. In a second step, the washing solution containing the CO2 is heated. The CO2 then leaves the solution and can be recovered in almost pure form as a product. The washing solution is continuously circulated without being used up. The CO2 obtained in this way is then bottled and used in the project for further investigations into geomethanisation. Amine scrubbers are state of the art in the natural gas and biogas industry. They have hardly been researched in steel production to date. The goals of the C-CED project include acquiring operating experience, investigating new absorption media and optimising processes.

www.wiva.at/project/c-ced/?lang=en

1 Project partners: RAG Austria AG (project coordination); ACIB GmbH; Axiom Angewandte Prozesstechnik GmbH; Energie AG Upper Austria; Energy Institute at JKU Linz; K1-MET GmbH; University of Natural Resources and Life Sciences, Vienna, Department IFA Tulln Institute of Environmental Biotechnology; WIVA P&G; voestalpine Stahl GmbH

2 www.rag-austria.at/en/research-innovation/carbon-cycle-economy-demonstration.html

The project is being carried out as part of the Hydrogen Initiative Energy Flagship Region Austria Power & Gas (WIVA P&G).

www.wiva.at