Typically, industrial facilities such as energy conversion systems and production units in all sectors reach maximum efficiency (as regards energy consumption, yield and cost effectiveness) at design capacity. Because of safety restrictions, though, industrial facilities are particularly difficult to control in this region.

To fulfil the tight requirements applying to the performance, efficiency, duty factor and reliability of industrial facilities, complex automation solutions are needed. This is particularly true where embedded systems are employed in large-scale and specialized apparatus engineering, such as energy conversion systems, where flexibility and efficiency in production and fabrication are decisive. Other factors that affect how production facilities are operated include rising energy costs, more emphasis on environmental issues, and government incentives (CO2 certificates). Classical (rigid) automation systems cannot satisfy these complex, partially divergent requirements, or only to a limited extent.

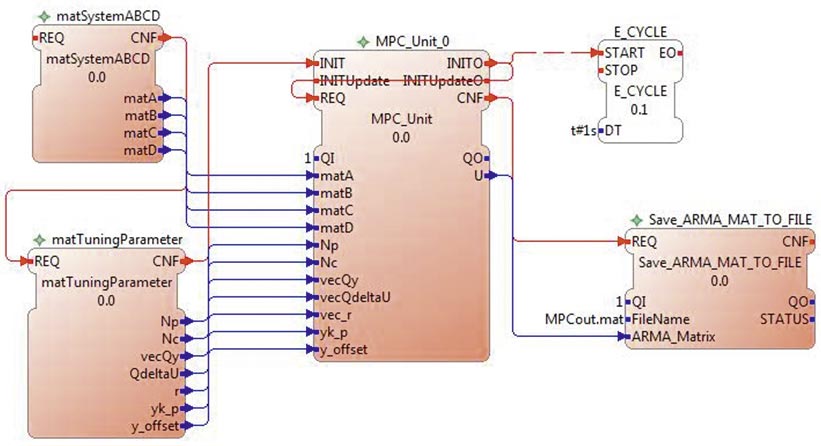

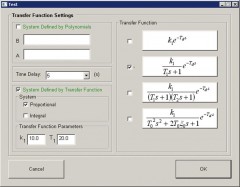

At Vienna University of Technology (ACIN – Automation and Control Institute) in cooperation with VOIGT+WIPP GmbH a new infrastructure is currently being developed to make it possible to combine modern control algorithms with classical control functions, so as to improve energy efficiency in a wide range of industrial applications. With the E3ICP a platform for optimization control on the basis of the IEC 61499 standard (international standard on function blocks for industrial automation), applicable to all sorts of automation systems, is being developed.

With the control structures employed (model-predictive control (MPC), fuzzy expert systems, internal model control) it is possible to fulfil the diverse requirements for stable operation at maximum efficiency, even under awkward conditions and in the case of malfunctions. With additional components evaluating the quality of control and system stability accurately is straightforward. In the meantime this control and optimization infrastructure (with real-time capability) for industrial applications has been demonstrated in a pilot biomass combustion facility; the results from this project can now be adapted to other sectors, such as the paper and timber industries

Share