The ERA-NET project EnCat is dedicated to the development of a new concept for producing high-quality pyrolysis oil from biomass at high yield. The Austrian company BIOS Bioenergiesysteme GmbH is part of an international joint project along with eight industry and research partners from four European countries.1

The bio-oil produced with current pyrolysis processes has some disadvantages when used for electricity and heat generation or as an automotive fuel. These include high levels of oxygen, water and water-soluble components (acids), poor miscibility with fossil fuels, insufficient chemical stability, and high viscosity. The goal of the EnCat technology is to generate a higher quality bio-oil from biomass that is suitable for diverse applications.

Bio-oil is produced via biomass pyrolysis, a thermo-chemical process in which the biomass is split into solid, liquid and gaseous components at high temperatures without the presence of oxygen. With fast pyrolysis, the biomass is rapidly heated to about 500 °C for a high pyrolysis oil yield. There are a number of ways to process and utilise bio-oils. Alongside use for energy purposes as fuel or heating oil, it can also serve as a raw material for various chemical applications.

Innovative Procedure

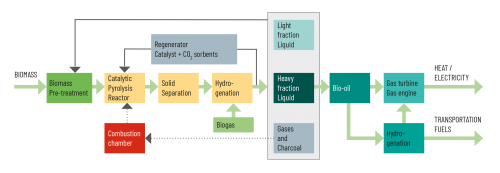

To utilise both wood biomass and agricultural by-products within the new concept, special pre-treatment steps are developed for the biogenic raw materials. The pre-treated biomass should then by pyrolysed in a reactor, using deoxidation catalysts. The concept foresees a simultaneous CO2 capture with sorbents and in-situ hydrogen generation through the water-gas shift reaction. The oil obtained after condensation can either be purified and hydrogenated to produce higher-quality bio-oil for various applications, or it can be used directly in gas engines and gas turbines. Modified burners for gas turbines are also being developed as part of the project for this purpose.

Biomass Pre-treatment

BIOS Bioenergiesysteme is testing various methods for biomass pre-treatment to reduce the contents of alkali and alkaline earth metals (AAEMs, i.e. potassium, sodium, calcium and magnesium) in the biomass. These elements promote reactions that lower the quality of the pyrolysis oil. The test runs showed that the amounts of AAEMs in woody biomass can be reduced by roughly 75% through extraction (known as leaching) under moderate temperature and residence time conditions using simulated wood acids, which are a result of the pyrolysis process, and can be separated from the pyrolysis oil (light liquid fraction, largely acetic acid). Leaching with water allows approximately 33% of the AAEMs to be removed. For agrofuels, which show significantly higher contents of AAEMs, reduction rates of about 85% were seen when treated with the simulated light liquid fraction, and 60% when leached with water.

Catalytic pyrolysis

The quality and yield of the resulting bio-oils can be improved through the use of deoxygenation catalysts and CO2 sorbents in the pyrolysis process. The project partners University of Twente (NL) and KTH Kungliga Tekniska högskolan (SE) are conducting laboratory tests with various catalysts and process parameters in order to optimise the process. Initial tests with pre-treated biomass showed positive results with regard to high achievable conversion and reaction rates, compared with pyrolysis of untreated biomass.

Combustion of bio-oil in gas turbines

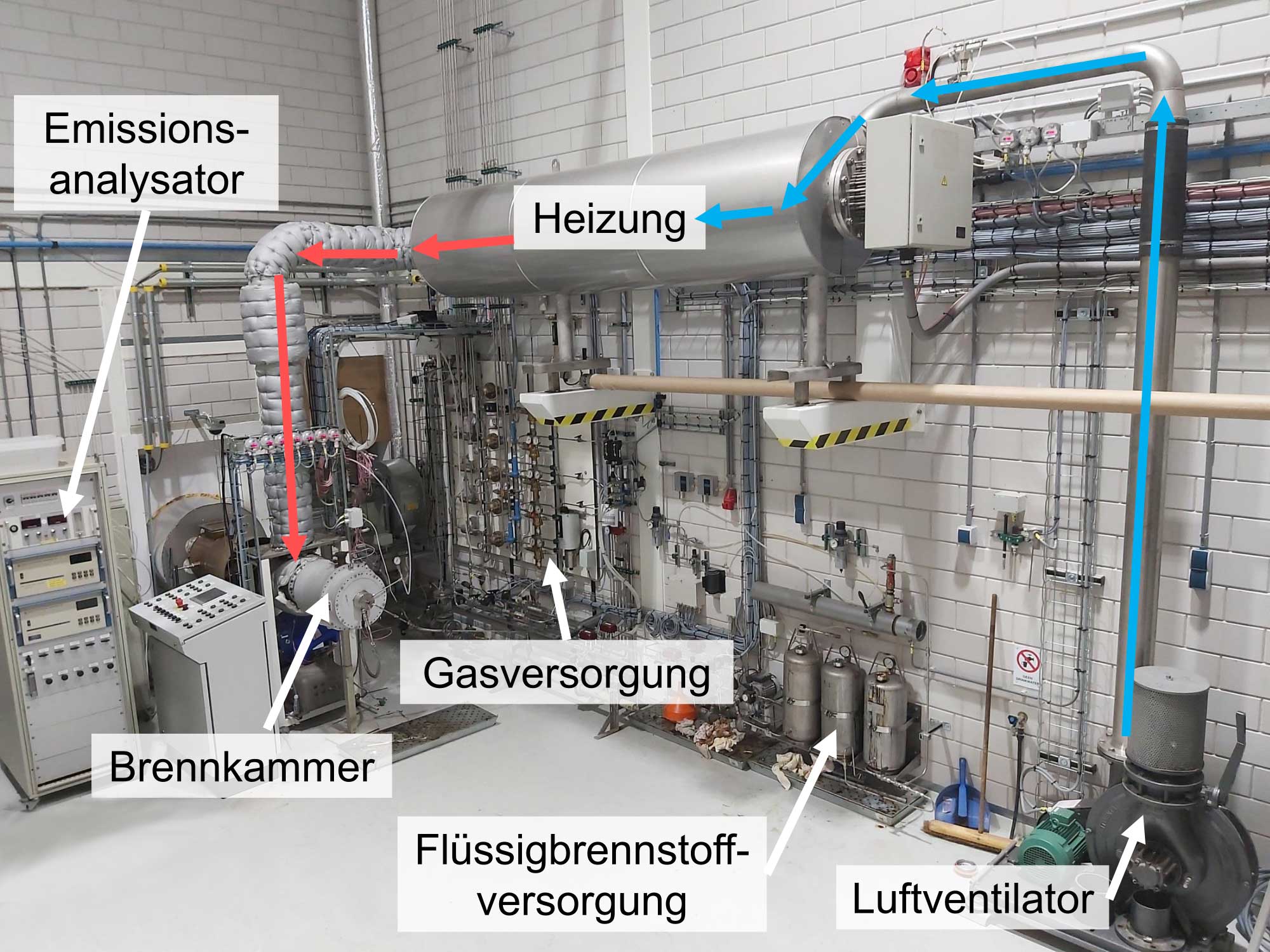

The company OPRA Turbines (NL) develops and produces gas turbines that can utilise a wide range of liquid and gaseous fuels. Computational fluid dynamics (CFD) simulations carried out by BIOS and UT, as well as experimental research, should generate insights into the atomisation and combustion of bio-oil in gas turbines. A gas turbine system for the use of bio-oil from cata-lytic pyrolysis is being optimised at the OPRA test bench. The main challenge lies in developing a combustion chamber and an air staging concept that ensure complete combustion with low CO and NOx emissions. Measurements of bio-oil atomisation (UT) and test runs with grid measurements of the temperatures in the burner (BIOS) support the development of a new burner design.

Refining bio-oil

To obtain a higher-quality bio-oil for various applications, the produced pyrolysis oil should be catalytically hydrogenated, and associated testing of various processes and catalysts is under way at the Institute for Chemical Processing of Coal ICHPW (PL).

The international collaboration should result in a full-scale concept for the EnCat technology. The development of a technically and economically competitive technology is further supported by accompanying techno-economic analyses and life cycle assessments of the entire process chain (from the feed material to electricity and heat production via turbines and engines or bio-oil utilization as transportation fuel).

1 Project partners: BIOS Bioenergiesysteme GmbH (AT), University of Twente, UT (NL, coordinator ), Alucha Management B.V. (NL), OPRA Turbines International BV (NL), Kungliga Tekniska högskolan, KTH (SE), RISE IVF (SE), Institute for Chemical Processing of Coal, ICHPW (PL), HIG Polska Sp. (PL)