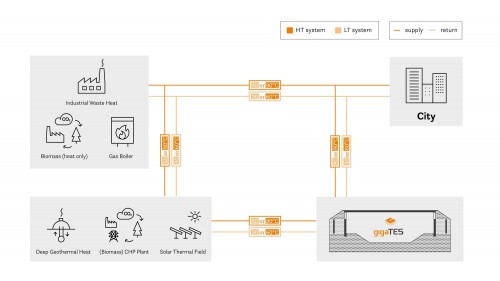

District heating networks that are supplied entirely with renewable energy sources require very large storage systems so that they can store the large quantities of renewable heat and waste heat needed for the winter during the summer, thereby enabling a high degree of flexibility. The volume of these giga-storage facilities must be up to ten times that of the storage systems used today (with 200,000 m3). In urban areas, these types of large-scale heat accumulators can only be built underground. This places high demands on the technology, materials and construction of these giga-storage systems.

Large-scale flagship project

The GigaTES project was aimed at developing giga-scale storage system concepts for urban quarters that are supplied exclusively or to a high degree with renewable energy sources. A total of 18 international partners from research and industry1 worked together under the leadership of AEE INTEC. These included material and component manufacturers, contractors and engineers, energy supply companies as well as national and international research institutes. All important aspects that are relevant in the planning, construction and operational phases of large-scale thermal energy storage systems were covered as part of the project. Solutions were sought that could be implemented in Austria.

Research priorities included:

> new materials for watervapour-tight films, with a focus on long service life and high storage temperatures

> new building constructions for walls, floors and covers of the heat accumulators

> tools for cost optimisation of different building concepts

Furthermore, calculation methods were developed for integrating the storage systems into district heating networks and for estimating the economic efficiency at material, component and system level. Moreover, simulations were carried out for designing and evaluating the thermal energy storage systems. These take into account specific boundary conditions such as size, system, location and hydrogeology.

Case studies for two heating networks

Two representative case studies show that the integration of a large-scale heat accumulator can improve the overall performance of the system by significantly increasing the share of renewable energy sources in the district heating networks. The analysis involved a smaller heating network, in which a 100,000 m3 long-term storage tank is to be integrated, as well as a medium-sized heating network with a storage volume of 1,200,000 m3 . The primary goal is to reduce the running times of the fossil peak load boilers in the winter months significantly by storing surplus solar thermal and geothermal heat from the summer. Two variants were defined for each system to represent high-temperature systems (90°C/60°C) and future low-temperature systems (60°C/30°C). The newly developed cost tool is used to determine the most favourable storage concept for each application and boundary condition.

Innovative construction

The innovative construction concepts can provide significantly larger volumes than previous construction variants. Suitable design variants were developed for different volume sizes, surface area availability and geotechnical ground models. One important issue is cost-effective thermal insulation, which should reduce heat loss and protect the groundwater from overheating. A special requirement involves the storage of water at high temperatures over longer periods of time. Significant heat loss can occur here. The “insulating bored pile wall” was developed and patented for this application, a solution with potentially low installation costs and very good thermal material properties.

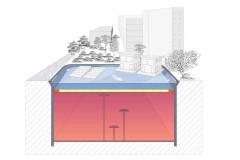

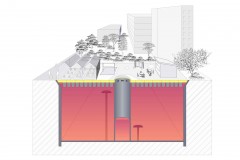

Innovative cover

The cover for the storage tank is a key component and is crucial in terms of cost-effective operation of the heat accumulator. Two innovative cover concepts, a submerged and a floating variant, were also developed and patented as part of the project. These covers can be used as recreational space, for greenhouses or for the installation of solar thermal and PV systems.

Durable materials

Various new polymeric materials were tested as liner for the storage and their service life was estimated using experimental ageing data. For the best-performing polypropylene type, average service life values are in the range of 31 to 35 years. Periods of well over 50 years were determined for low-temperature giga-scale storage systems with operating temperatures in the range of 35 to 80°C. The new material therefore has a service life that is more than a factor of 2 longer than that of conventional polyethylene liner materials.

www.gigates.at/index.php/en/

„For a successful energy transition, it is not only important to increase the share of renewable energy sources but it also requires an expansion of storage capacities. Therefore, innovative storage technologies are an essential building block for the functioning of the energy system of the future. As a Green Tech Company, we have already been working on the development of storage technologies for several years. In Salzburg’s district heating system, larger heat accumulators will play a key role in the future. That is why we have been actively involved in research projects on the technical feasibility of large-scale heat accumulators in urban areas for a long time.“

Brigitte Bach

Member of the Board Salzburg AG

1 Project Partners AEE INTEC (project management), SOLID Solar Energy Systems, JKU Linz/Institute of Polymeric Materials and Testing, University of Innsbruck, Ingenieurbüro ste.p, AGRU Kunststofftechnik GmbH, Metawell, Bilfinger VAM Anlagentechnik GmbH, Geologie und Grundwasser GmbH, PORR Bau GmbH Tiefbau, Lenzing Plastics GmbH, PlanEnergi, Gebriel-Chemie Gesellschaft m.b.H., Smart Minerals, Wien Energie, Solites, Salzburg AG, GVT Share