Various industrial processes involve large amounts of waste heat, which has to be disposed of at extra expense in many cases. But this waste heat is a valuable resource, given that it is generally at a temperature of around 30 to 60°C – significantly higher than that of ambient air or the ground. These days large scale heat pumps for industrial processes are usually adapted to the particular circumstances and produced in short runs; the refrigerants commercially available impose a temperature limit of at most 80°C on the heat sink side, e. g. top water. Quite a number of industrial processes require heat at higher temperatures, though, up to 110°C.

By means of high-temperature heat pumps industrial processes could be made much more energy-efficient. In the HyPump project the Institute of Thermal Engineering at Graz University of Technology has developed an highly-efficient hybrid heat pump to recover waste heat in industry, with AIT Austrian Institute of Technology and Frigopol Kälteanlagen GmbH as project partners.

Benefits of the new development

With the innovation of a combined absorption/compression heat pump using a special working pair it is possible to achieve high supply temperatures (above 100°C) without increasing the facility’s operating pressure. The „HyPump“-concept is scaled for low to medium ratings and follows these objectives:

> high efficiency even at high temperatures, so carbon-dioxide emissions can be reduced significantly

> wide range of application, since the process can be adapted to the heat sink temperature desired

> medium capacity range (approx. 50 kW) for decentralized deployment

> cost-effective even with modest ratings, thanks to the use of standard components

> use of an environment-friendly working substance (a blend of ammonia/lithium nitrate)

Project results

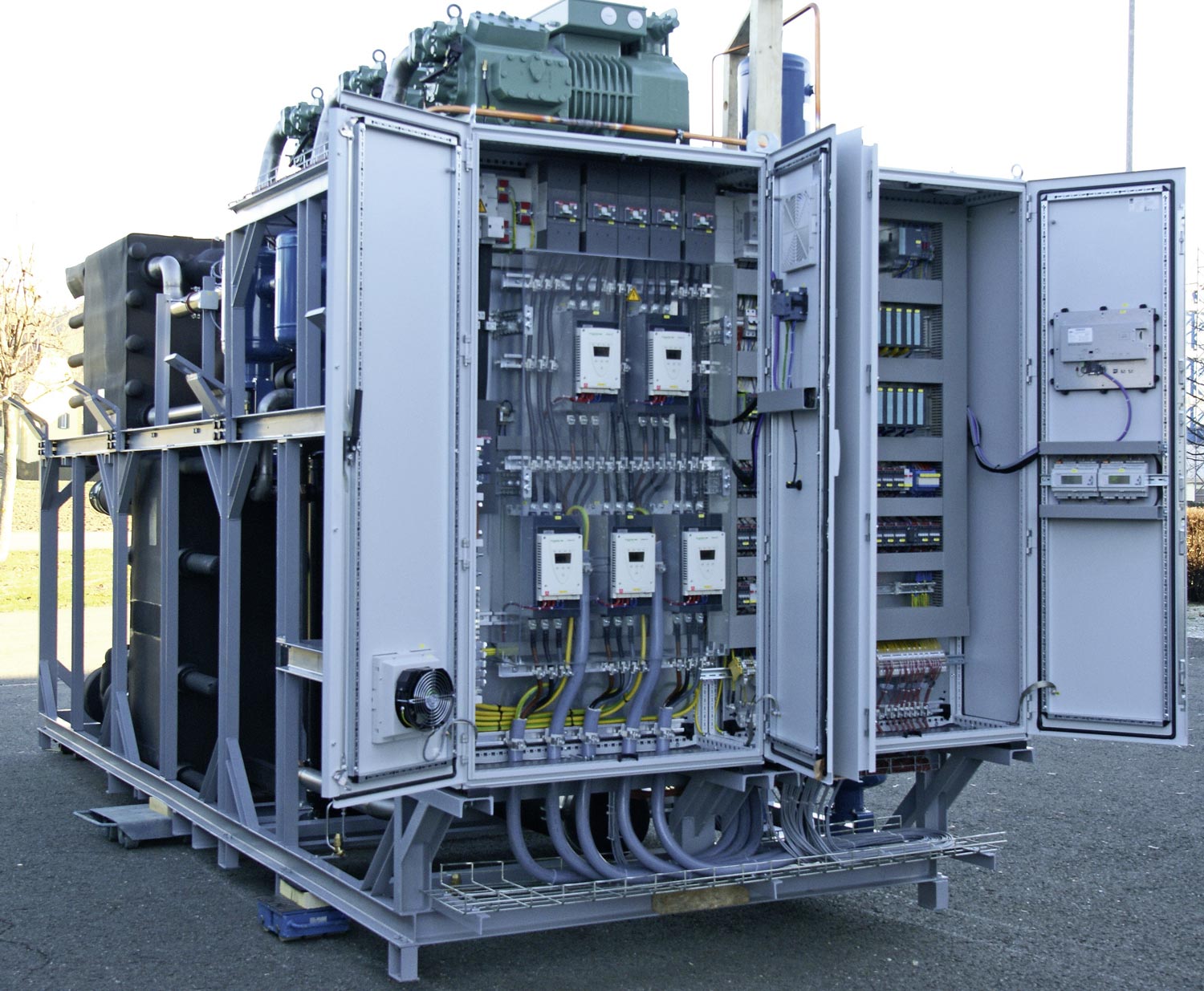

In the course of the project a prototype hybrid heat pump was installed at Graz University of Technology, to make it possible to assess the design as regards capacity and efficiency under different operating conditions. Individual components were evaluated in detail and potential for improvements was identified. The results show that with extended control options the system of a hybrid heat pump is of interest for a wide range of applications, particularly at higher temperatures.

As part of the project a cost analysis was carried out and the relative cost of the individual system components examined in detail. The compressors, the solution pump, the plate heat exchanger and erection and servicing account for 70 % of total cost. With the extended control options more instrumentation is needed, too. Cost reduction potential is given by making changes in the design and standardization.

The findings can be used to compare performance and cost structure with those of alternative heat delivery systems in the case of future practical applications; they serve as a basis for preliminary investigations in connection with additional research projects or pilot facilities.

CEO , Photo: Frigopol Kälteanlagen GmbH

Johann Herunter

CEO Frigopol Kälteanlagen GmbH