With a final energy usage of 2,140 PJ, the iron and steel industry is one of the biggest energy users in the European Union*. As well as the energy-intensive and high-emission blast furnace method used in steel production, electric furnace steelmaking is used worldwide. Scrap steel is melted down in electric arc furnaces and then processed into high-quality steel products. The melting of recycled scrap steel requires the use of less energy and results in lower CO2 emissions compared with the conversion of iron ore to iron in a blast furnace. The electric arc furnaces can also be operated using power from renewable energy sources. However, the heating of some auxiliary components takes place both in the blast furnace and in the electric arc furnace route with gas firing.

The OxySteel project, managed by the University of Leoben – Chair of Energy Network Technology in cooperation with Breitenfeld Edelstahl AG and Messer Austria GmbH, is researching and testing ways of increasing energy efficiency and reducing CO2 emissions in electro-steel plants. The project team is developing an innovative process design integrating oxygen combustion and CO2-separation (CCU/Carbon Capture and Utilisation) into the production process. In addition, the potential for Demand Side Management in steel production is analysed.

Energy-efficient processes

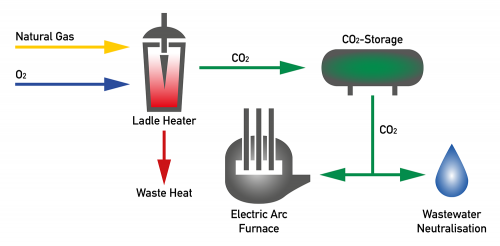

Oxygen combustion can be used in electro-steel plants to pre-heat ladle heaters as well as in heat treatment. Replacing the combustion air with pure oxygen leads to a higher flame temperature, lower exhaust gas losses and reduced nitrogen emissions. As part of the project, the Messer Oxipyr oxygen burner is being fitted with a special measurement sensor to achieve optimal control of the combustion process. Oxygen burners are up to 50% more energy efficient and produce a waste gas with a higher concentration of CO2. Some of the CO2 produced in the process is used for environmentally friendly wastewater neutralisation in the plant. The use of carbon dioxide instead of other chemicals to treat wastewater means that the salt content of the wastewater is lower. Research is also being conducted to ascertain whether some of the CO2 could be used for refining purposes in the electric arc furnace. The introduction of an O2/CO2-mix for iron refining should improve the melting behaviour and increase the iron yield for the same volume of scrap.

Trial runs in steel plants

The technologies developed as part of the project are being integrated into the production process in the Breitenfeld Edelstahl AG steel plant in Styria. Five conventional ladle heaters are being replaced by three new furnaces with oxygen burners. This is expected to significantly reduce natural gas consumption and, consequently, CO2 emissions. The internal plant usage of CO2 also has a positive effect on the energy and CO2 balances. The researchers expect annual energy savings of 12 GWh due to the implementation of OxySteel. This is the equivalent of around 10% of the annual natural gas requirement of a small town in Styria.

Using flexibilities

The process design also makes it possible to provide the necessary flexibility for integrating the power from fluctuating renewable energy sources such as wind power and photovoltaics, for example. The operational flexibilities will be assessed in the project and the potential for network services calculated from this. Due to its existing connection to the 110 kV high-voltage network and the possibility of connecting it to the 220 kV network, the location of the steel plant is suitable for making use of the internal operational flexibility of the plant as a regional or transregional flexibility option.

* Source: Energy Balance Sheets, 2014 data 2016.

OxySteel and SANBA (see page 8) are projects of the flagship region NEFI – New Energy for Industry, an innovative network made up of scientific institutes, technology providers and companies for the development and demonstration of key technologies for the decarbonisation of industry.

OxySteel and SANBA (see page 8) are projects of the flagship region NEFI – New Energy for Industry, an innovative network made up of scientific institutes, technology providers and companies for the development and demonstration of key technologies for the decarbonisation of industry.

www.nefi.at