The first external production facility for “green” hydrogen in Austria went on stream in the municipality of Gabersdorf in southern Styria in May 2023. The pilot project by Energie Steiermark1 is pursuing a holistic “power-to-gas” approach and trialling the integration of green-hydrogen production with load-flexible methanation and the storage and distribution of the renewable hydrogen and the green natural gas produced by synthetic means. The plant on the 10,000 m2 site consists of a large-scale PV facility with 6,000m² of collectors, an electrolyser to produce green hydrogen, a trailer filling system and the methanation unit, which is connected to an existing biogas plant.

A sustainable energy cycle

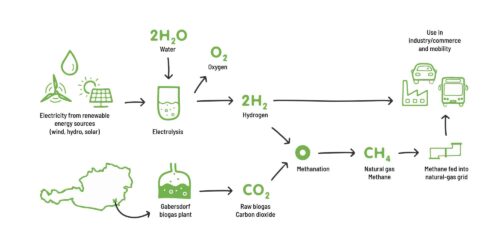

Using electrolysis, water is split into its constituent elements – hydrogen and oxygen – with the help of electricity from renewable sources. The hydrogen thus released can be fed straight into vehicles or used for a range of industrial processes as a CO2-free energy carrier without having to be converted into anything else. Alternatively, it can be converted into methane gas in a carbon-neutral way by adding raw biogas and then fed into the existing natural-gas grid. In other words, hydrogen enables a closed, sustainable and emission-free energy cycle.

Integration with a biogas plant

The methanation technology used was developed and applied at laboratory scale in a previous project. This technology is now being trialled on a large scale as part of the “Renewable Gasfield” project, including direct integration with a biogas plant. Only substances that would damage the catalyst are separated out by means of adsorption when the biogas is pre-treated, allowing the biogas to be added directly into the methanation process. This does away with the usual costly carbon separation process prior to feeding into the natural-gas grid.

PROJECT FACTS & FIGURES

> Start of construction: March 2022

> Commissioning: May 2023

> Total invested: around EUR 10.5 million (including EUR 2.6 million in funding)

> Size of the power-to-gas plant: 10,000 m2

> Large-scale PV facility with collectors covering 6,000 m² (850 kWP)

> Up to 300 t of hydrogen produced per year

> Around 5,200 t CO2 saved per year

> Operating hours, electrolysis: 7,000 hours per year

> Operating hours, methanation: 1,000 hours per year

Results and prospects

The modular design of the infrastructure concept enables it to be expanded independently and all parts of the system to be adapted to fit future requirements and business models.When it has reached its full size, the plant is expected to generate up to 300 tonnes of green hydrogen a year. The green gas is piped into trailers, allowing it to be stored and transported, and is available for use in a range of industry sectors. The first major customer is the industrial company Wolfram Bergbau und Hütten AG, a subsidiary of the global Sandvik Group. The St. Martin-based firm is the global market leader in tungsten powders and will be purchasing around 70 tonnes of green hydrogen a year for its energy processes.

Energie Steiermark is planning to expand its electrolysis capacity to 150 MW by 2035 to produce green hydrogen at “on-site” plants for industrial customers and run Styrian “Energy Hubs” at strategic nodes in the grid. The energy supplier intends to build around 200 km of hydrogen grid infrastructure to enable the efficient and safe transport as well as the distribution and integration of green gases. As well as in industry, Energie Steiermark’s green hydrogen is also to be used in the mobility sector in the future, with heavy-duty transport seen as harbouring great potential in this regard. The first customers for ultra-pure green hydrogen could potentially be freight forwarders or construction firms that are currently launching pilot projects and/or buying their first trial vehicles in a bid to decarbonise their fleets.

„Green hydrogen is a key component of the energy transition. Building on the experience gained from our Gabersdorf pilot project, we’re planning to expand hydrogen production systematically together with industry partners – we’re looking at 150 megawatts as the first step. At the same time, we’re working on making our existing natural-gas grid infrastructure compatible with the integration of green gases. We’re eyeing up pipelines with a total length of some 200 kilometres for a technical upgrade.“

Christian Purrer und Martin Graf

Managing Board of Energie Steiermark

www.wiva.at/project/renewable-gasfield

1 Project partners: Energie Steiermark Technik GmbH (project coordination), Energienetze Steiermark, University of Leoben/Faculty of Process Engineering in Industrial Environmental Protection, HyCentA Research GmbH, Energy Institute at Johannes Kepler University Linz, Energieagentur Steiermark, Government of the State of Styria, A15 – Energy and Housing Department

The Renewable Gasfield project forms part of the WIVA P&G – Austria Power & Gas Model Region Hydrogen Initiative research initiative.

www.wiva.at