Conventional compression heat pumps have been little used in industry up until now because their thermodynamic properties significantly limit their usefulness in industrial processes. Rotation heat pumps from the Austrian company ecop Technologies GmbH are a new development. These harness an innovative technology and were specifically designed for industrial use. Unlike compression heat pumps, they can handle flexible processes and temperatures ranging from -20°C to +150°C and work with a non-flammable, environmentally friendly gas. The technology has already been successfully demonstrated on prototypes and in the operation of a reference system. So far, however, it has only been possible to control the rotation heat pump manually.

Functional control of rotation heat pumps

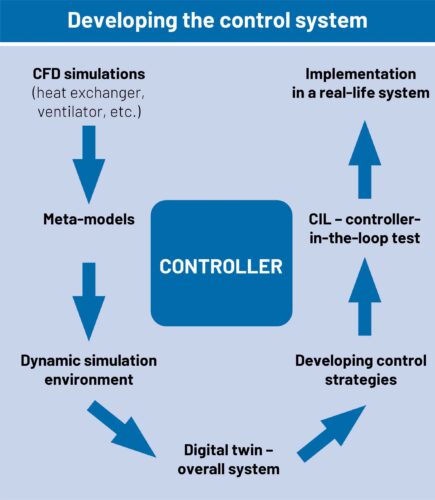

Since rotation heat pumps have a fundamentally different design and operating principle to conventional ones, their control systems and strategies cannot be transferred from one to the other. As part of the ROHAN project and in partnership with AIT Austrian Institute of Technology,1 the company is developing a concept for the functional control of rotation heat pumps that is to be implemented and trialled in real-life operation further down the line. In the first step, the physical interrelationships between the various thermodynamic processes that components of the rotation heat pump undergo have to be identified and analysed. A digital twin of the system is then generated in a dynamic simulation environment based on these findings. This forms the basis for devising and designing a functional control system for the rotation heat pump. The control concept developed is to be tested on the controller hardware (“controller-in-the-loop”) and then demonstrated on a real-life system at proof-of-concept stage. In particular, ecop Technologie GmbH is contributing its expertise to the process, to simulating the components and to implementing the controller in the machine’s control system. AIT Austrian Institute of Technology provides extensive knowledge of compression heat pumps and using dynamic simulation environments to design complex controllers.

„The ROHAN project is helping to bring the market launch of the rotation heat pump a lot closer. Having a digital twin allows us to study the control technology in our innovative rotation heat pump in great depth. In AIT, we’ve found the perfect project partner for turning our ideas into reality. The ability of our systems to withstand high temperatures means that we’ll be able to provide a key technology for decarbonising heat generation in industry.“

Bernhard Adler

CEO ecop Technologies GmbH

Initial results

A number of models of individual components have already been created and simulated using computational fluid dynamics (CFD). These models were integrated into a dynamic simulation environment in initial tests and are now being studied in action. The results obtained to date are already indicating fundamental interrelationships between individual components. The team now wants to gain new insights into optimising the controller from a technical perspective by adding in more models and connecting them up in the dynamic simulation environment.

energieforschung.at/projekt/regelungstechnische-gesamtoptimierung-einer-rotationswaermepumpe-mittels-digitaltwins-rotation-heat-digital-twin/

1 PROJECT PARTNERS: ecop Technologies GmbH (project management), AIT Austrian Institute of Technology GmbH