One promising technology for storing electricity is adiabatic compressed-air energy storage, which can be used to supplement pumped-storage facilities on an industrial scale; it achieves up to 70 % efficiency. Work is currently in progress on developing this pioneering technology further in the Institute for Energy Systems and Thermodynamics at Vienna University of Technology. The search is on for a cost-effective, resource-efficient solution that combines full functionality with minimal impact on the surrounding ecosystem.

In the project SEES – Sublake Electrical Energy Storage a system has been developed for a flexible compressed-air storage facility that can be installed on the floor of Austrian lakes and operated at constant pressure (isobar). Here heat storage is taken care of by the new SandTES heat storage system, which the project partners have patented. The issue to be investigated (by example of Traunsee, Upper Austria) was whether SEES facilities with a capacity of 1 to 20 MWel can be implemented satisfactorily from an engineering and economic point of view.

The project ScACAES – Saline-Cavern Adiabatic Compressed-Air Energy Storage investigated the feasibility of using saline caverns resulting from salt extraction as compressed-air storage reservoirs with ACAES equipment. The current and future potential of sites in Austrian Salzkammergut for storing compressed air was assessed and a comprehensive strategy developed, covering both technical and process engineering requirements and a cost-benefit analysis. The project has yielded a list of usable and interconnectable caverns, with details of the capacity, depending on process implementation.

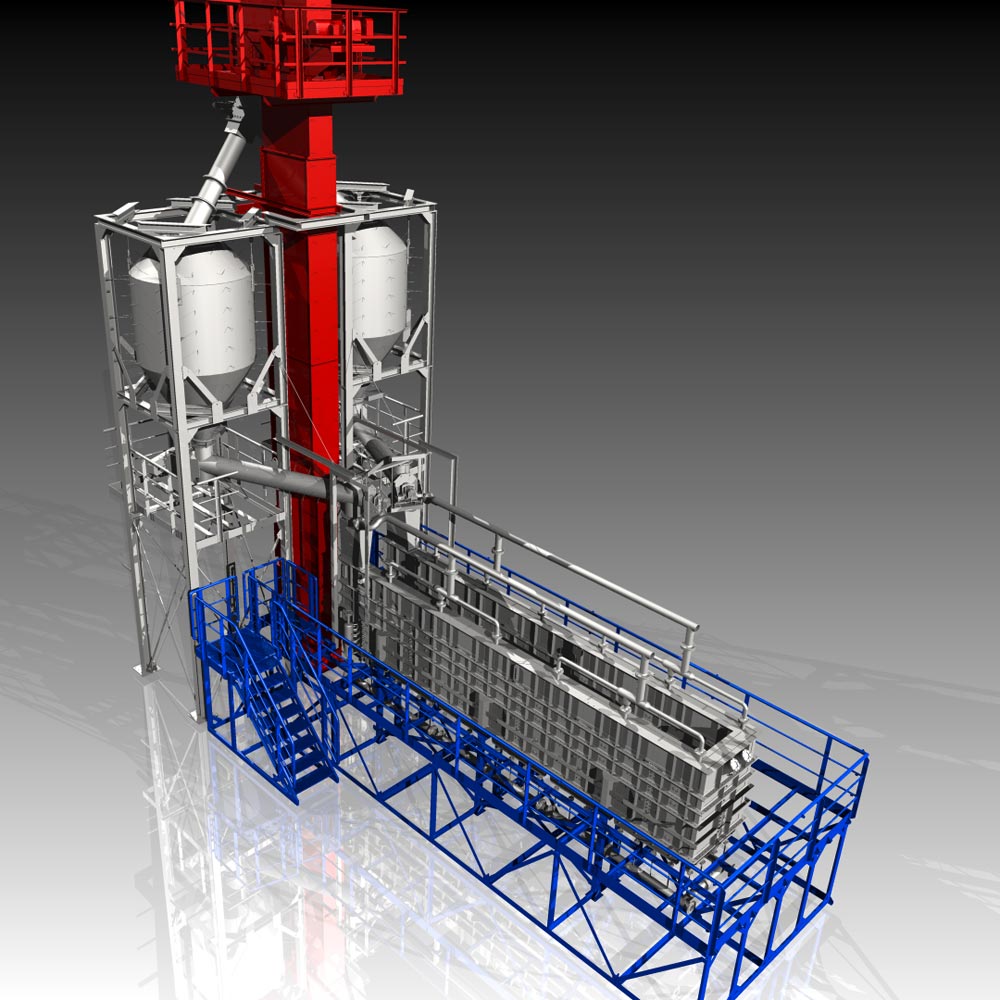

The recently developed SandTES system is based on active heat storage with sand transported through a heat exchanger. In the case of energy storage on an industrial scale equipment cost is largely dependent on the storage material selected. Sand is a natural product readily available all over the world, and thus an inexpensive storage medium. The sand is fluidized and passed through the heat exchanger over a stationary fluidized bed in counterflow; it behaves like an extremely viscous gas-particle suspension. In the course of the project the entire heat-exchange technology, a special distributor-plate design and a level resp. flow control mechanism were developed, so as to make flexible, dynamic operation possible. The SandTES high-temperature heat exchanger is one of the most important elements for implementing adiabatic compressed-air storage. The commissioning of a first SandTES pilot facility with a capacity of 280kWth is planned for 2016.

Source: Vienna University of Technology, Institute for Energy Systems and Thermodynamics

Compressed-air storage power stations use compressed air as an energy storage medium. Off peak, surplus electricity is used to pump air into a reservoir under pressure; when the demand for electricity increases, the compressed air generates electricity in a gas turbine. Until now the heat produced when air is compressed had not been utilized at a later stage; when the air is depressurized additional heat must be supplied externally from a combustion chamber.

In adiabatic compressed-air storage the heat released at the compression stage is stored and used at a later stage in the process; before air is depressurized it passes through a heat storage device, where it is heated up. In this way there is no need of natural gas to heat the air with, and the facility achieves greater efficiency.

Univ.-Prof. DI Dr. Markus HAIDER

TU Wien, Institut für Energietechnik und Thermodynamik