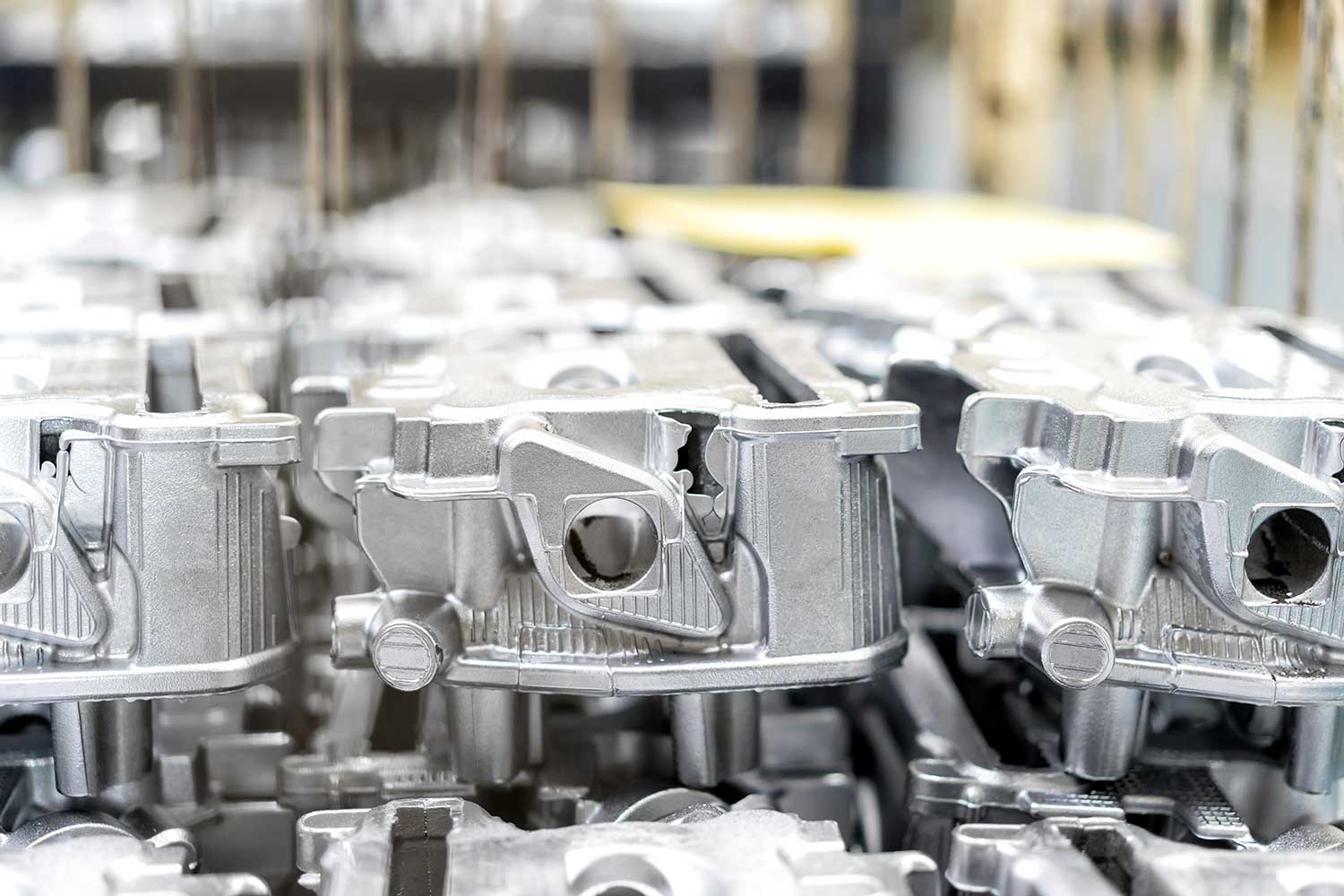

The automotive and automotive supply industries are amongst the most important economic sectors in the European Union, accounting for more than 10% of manufacturing jobs in the EU and around 4% of the European gross domestic product.

Source: ACEA, (2017), The Automobile Industry Pocket Guide 2017-2018

To reduce CO2 emissions in industry and small-scale manufacturing over the long term, energy requirements must fall and the use of renewable energies must increase. Solar process heat offers many opportunities for supporting industrial processes with renewable energy and for reducing the need for fossil energy sources. An economical implementation is particularly viable in situations when temperatures below 100 °C are needed, no waste heat can be used and where there is a constant heat demand, at least in the sunny months. Integrating solar heat is an option for heating networks, heated pools, machines and tanks, drying processes as well as for supplying hot water and for building ventilation systems, for example. Solar heat is CO2-free and can be combined with other heat sources such as heat pumps, combined heat and power units or gas, oil and biomass boilers. Despite its high potential, the market for this technology has only developed slowly to date.

International research cooperation

Within the scope of the D-A-CH initiative, the German-Austrian cooperative project SolarAutomotive was launched in 2016 under the management of AEE INTEC and the University of Kassel (Department of Solar and Systems Engineering)*. The aim of this transnational cooperation is to drive forward the integration of solar process heat in the automotive industry as well as in the upstream supply chain. Application examples and the implementation of flagship projects will provide innovative impulses and demonstrate the potential for CO2-free production. As the industry comprises a wide variety of production branches and processes, knowledge can be transferred to other industrial sectors (e.g. food and beverages, textiles, printed circuit boards, metalworking). To begin with, twelve sub-branches in the automotive and automotive supply industries were identified and the processes suited to a solar thermal energy supply due to their process requirements were determined. These key processes include, for example, electroplating processes in metal finishing, air conditioning measures in the automotive industry and washing and drying processes in the textile industry.

Based on the final energy usage of European industry and on the assumption that the entire industrial requirement for heat below 200 °C can be supplied via solar thermal energy, the potential CO2 savings are 25 million tonnes per year. In the automotive industry alone (excluding the automotive supply industry), this means 4.2 million m² of installed collector surface and an output of 2.4 gigawatts SHIP (Solar Heat for Industrial Processes).

Case studies

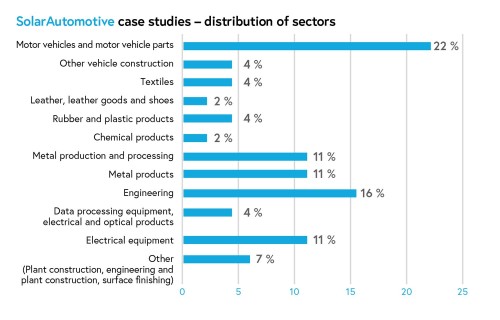

Within the framework of SolarAutomotive, 25 detailed case studies have been carried out in different countries identifying possible points of integration for supplying various production processes with solar thermal energy. The detailed simulations take into account numerous process parameters (temperature level, spreading, heating rates, etc.) as well as process engineering characteristics and product quality. This results in the choice of suitable collector technology and surface, storage, installation site and orientation of the system. The case studies confirmed the great potential of solar process heat in the automotive and automotive supply industries. The analyses show technically and economically practical system concepts of various sizes (solar thermal energy surface areas ranging from 50 m² to 3,200 m²). After a positive internal evaluation, the concepts are set to be implemented as the next step.

„Our vision at AT&S is to implement a sustainable energy supply at all our locations. And what could be more natural than using solar power to turn this vision into reality? The ‘SolarAutomotive’ project has identified a number of technically interesting possibilities for the use of solar process heat which we are currently evaluating and we hope to be able to integrate them into our energy concept.“

Heinz Moitzi

Chief Operations Officer (COO) AT&S

SolarAutomotive Guideline

Based on the results, a guideline was created with the aim of helping to make the use of solar process heat in the automotive and automotive supply industries more widespread. Alongside information on potential usage options and integration concepts, simple, tailored tools were made available for the design and economic valuation of a system. A preliminary design tool and a detailed simulation tool (SolarSOCO) enable rapid or in-depth calculations.

www.energieforschung.at/projekte/847/solare-prozesswaerme-fuer-die-automobil-und-zulieferindustrie (in german)

* PROJECT PARTNERS:

S.O.L.I.D. GmbH, KPV Solar GmbH, Stiftung für Ressourceneffizienz und Klimaschutz (STREKS – Foundation for Resource Efficiency and Climate Protection), Fachbereich Umweltgerechte Produkte und Prozesse (UPP- Department of Environmentally Friendly Products and Processes) at the University of Kassel